World HeritageTomioka Silk Mill: Introduction to the Four Sites

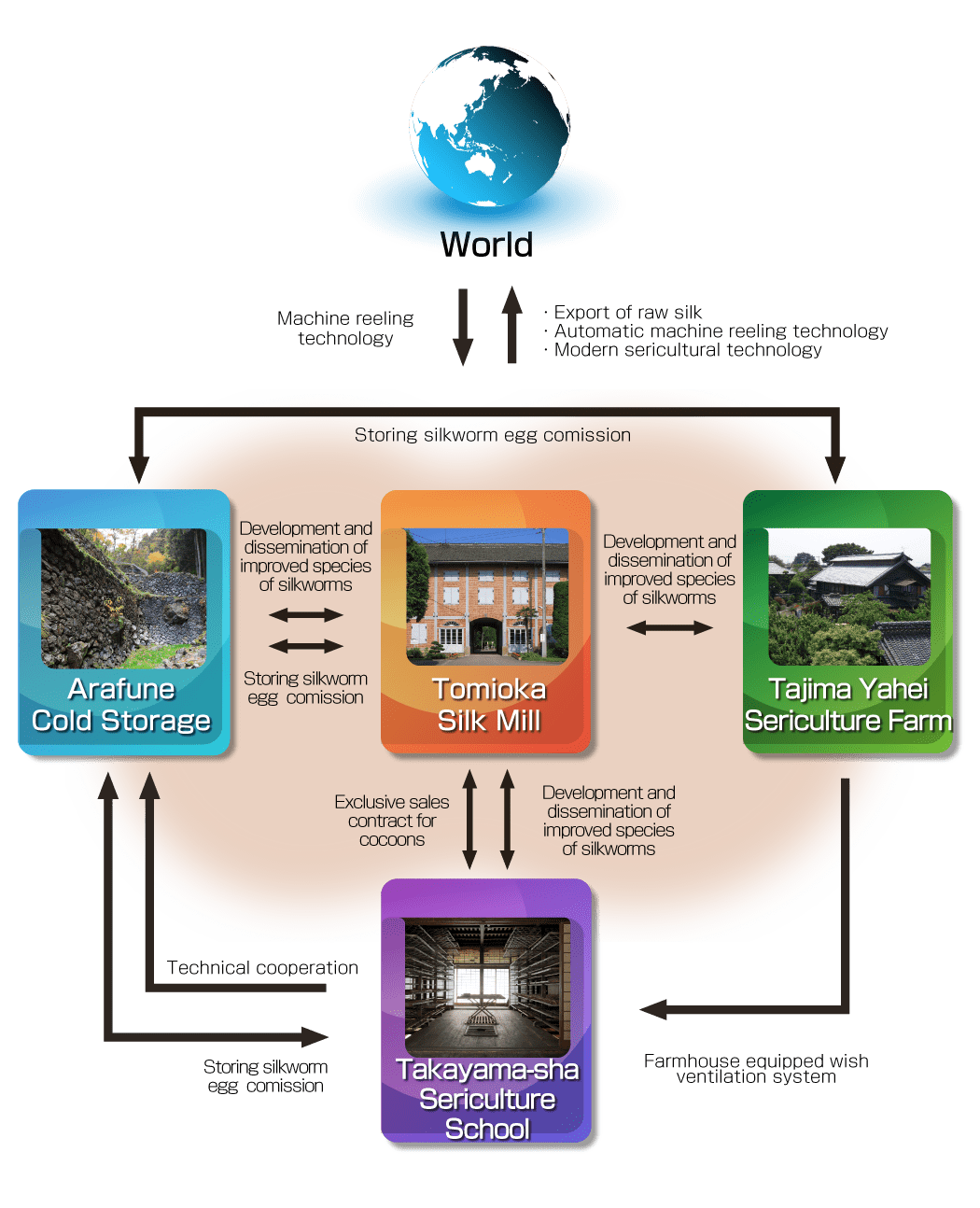

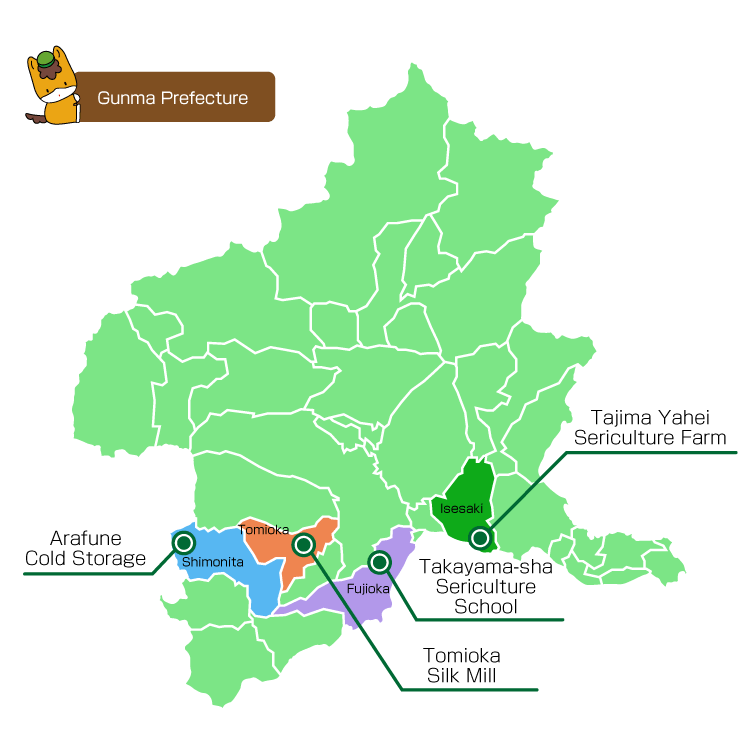

The 2014 World Heritage listing “Tomioka Silk Mill and Related Sites” is comprised of four sites: Tomioka Silk Mill, Tajima Yahei Sericulture Farm, Takayama-sha Sericulture School, and Arafune Cold Storage. Each played a significant role in Japan’s industrialization of silk production. Tomioka Silk Mill was Japan’s first mechanized silk reeling mill, Tajima Yahei Sericulture Farm and Takayama-sha Sericulture School improved sericulture methods and silkworm strains, and Arafune Cold Storage made it possible to control when silkworm eggs hatched, thus increasing the number of growing seasons per year.

World Heritage“Tomioka Silk Mill and Related Sites”

(History and Background)

Japan emerged from two and a half centuries of isolation and feudal rule in the Meiji era (1868–1912), rapidly modernizing and industrializing to become a major world power. The Japanese government facilitated rapid industrialization by importing technology and inviting advisors from overseas. The government began by developing existing cottage industries and industries where raw materials were readily available.

Silk, especially raw silk, was exported to Europe as soon as Japanese trade was opened in the middle of the nineteenth century, and demand was strong. This made silk a prime candidate for the development of industrial production techniques.

Tomioka Silk Mill

Tomioka was chosen as the site for Japan’s first mechanized silk-reeling mill because it was in the center of one of the country’s most prolific silkworm-producing regions. The mill represents Japan’s first use of Western technology and Western advisors to create a full-scale factory system for the production of silk thread.

Tomioka Silk Mill’s main buildings were constructed by Japanese carpenters following French designs. They laid red brick, an innovative material in Japan at the time, around wooden frames and used Japanese plaster for finishing.

The mill opened as a government-operated enterprise in October 1872 under the supervision of French advisors who lived on site.

Tomioka Silk Mill became a model mill and would-be mill owners in Japan travelled to Tomioka to see firsthand the cocoon warehouses, the French-made reeling machines, and the steam power plant. They also viewed the mill’s other facilities including the infirmary, cafeteria, and living quarters for the office staff and mill workers.

Modern machine reeling necessitated an increase in the production of raw silk from silkworm cocoons, and sericulturists succeeded in boosting the number and quality of cocoons they could produce for the mill.

Women Mill Workers

The mill’s advisors and management suggested that women be hired to operate the reeling equipment. It was believed their smaller hands were better suited to the delicate work of extracting threads from silkworm cocoons and reeling them onto spools.

Initially management struggled with recruitment, since most Japanese women stayed at home. In addition, after two and a half centuries of isolation, local women were reluctant to work with non-Japanese people. Lack of exposure to Western culture resulted in misunderstandings, such as the rumor that the French advisors drank blood. This rumor started when locals saw the French drink red wine, a liquid unfamiliar to the average Japanese. It was not until 14-year-old Odaka Yu, daughter of the mill’s first head manager, agreed to become the first mill hand that women came to work in the mill.

The women worked six days a week and lived in dormitories inside the mill complex. French women brought to the mill to train the new recruits also had special housing on site.

The Japanese mill workers usually were in their teens or twenties and left after a few years to marry.

Improvements to Sericulture

Raising silkworms from the egg stage to the cocoon stage commonly took place in the upper floors of traditional farmhouses where farmwives had the primary role in caring for the silkworms.

Silkworms are delicate and difficult to raise. They are only able to thrive within certain temperature and humidity levels. Several sericulturists experimented with solutions to this problem around the same time that industrialization was expanding demand for silkworm cocoons.

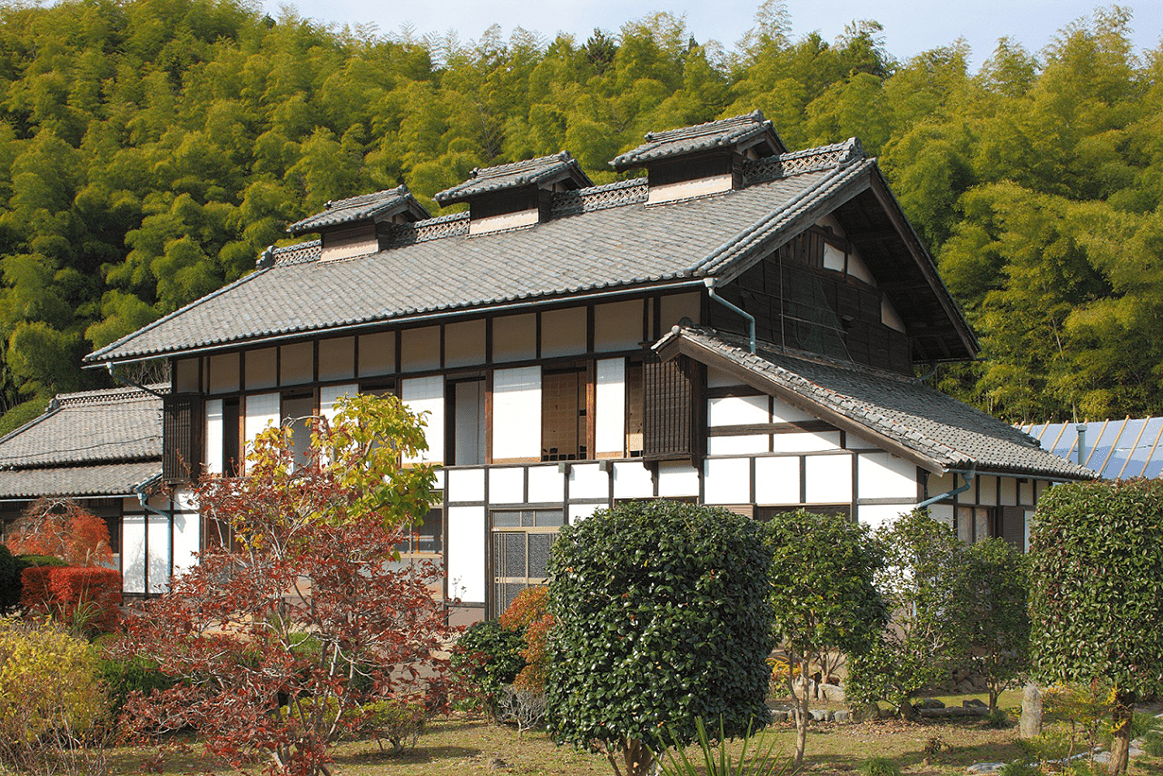

Tajima Yahei (1822–1898) was one of the earliest sericulturists to develop improved methods for raising silkworms. In 1863, he rebuilt his farmhouse in Sakai-Shimamura, east of Tomioka on the banks of the Tone River, adding a koshi-yane, a raised section of the roof with openings for ventilation running the length of the ridge pole. The koshi-yane circulated air into the uppermost floor, where the silkworms were raised, and significantly improved their survival rate. Based on this success, Yahei went on to develop a sericulture process, called seiryo-iku (“clean and cool nurturing”), stressing ventilation, which rapidly became widespread. Yahei’s 1863 farmhouse, especially his koshi-yane, became a prototype for farmhouses where sericulture was practiced. The house is still occupied by his descendants.

Other sericulturists also worked to improve silkworm farming methods. Takayama Chogoro (1830–1886), a village headman in nearby Takayama, conducted experiments to understand and create the optimal living conditions for silkworms. He converted his family home into a laboratory where he built on Yahei’s seiryo-iku method by also controlling temperature and humidity levels using a small charcoal brazier. This sericulture method, combining ventilation with temperature and humidity control, was called seion-iku (“clean and warm nurturing”).

In 1884, Chogoro turned his family farm into a sericulture school known as Takayama-sha to teach his new method of seion-iku to students from around Japan, as well as parts of China and the Korean Peninsula. The students lived in an on-site dormitory and raised silkworms as part of their studies.

Controlling Hatching

Sericulturists realized they could raise more than one crop of silkworms each year if they could delay the hatching of eggs by keeping them cool.

Arafune Cold Storage, west of Tomioka near Mt. Arafune, was developed in the early twentieth century to keep silkworm eggs cool before the advent of electric refrigeration. The site takes advantage of a natural cooling phenomenon. There is a 400-meter-long tumble of boulders on the mountain’s steep slopes, which is the result of an ancient landslide. Snow and rain falling on the mountain become trapped in gaps between the boulders, forming ice and creating cold air. Cold air, being denser, flows down the mountain through the gaps, becoming colder and pulling warm air after it, which is also cooled by the snow and ice between the boulders. The cold air emitted at the bottom of the boulders is never above 5°C in summer.

Stone walls built at the base of the boulders captured the cold air to cool multi-level wooden warehouses that were constructed inside. Each wooden structure housed boxes of specially marked cards on which silkworms had laid their eggs. These cards made it possible to easily label, catalogue, and ship the eggs after they had been tested for disease. The cards were sent to Arafune Cold Storage from across the country, to be returned when needed.

World Heritage Status

Arafune Cold Storage, Tajima Yahei Sericulture Farm, Takayama-sha Sericulture School, and Tomioka Silk Mill were designated UNESCO World Heritage in 2014.

The first full-scale raw silk factory introducing machine-reeling technology from France.

Prototype of modern sericultural farmhouses utilizing a ventilation system on its tiled roof.

Birthplace of seion-iku, which became standard for this modern Japanese sericultural technology.

The largest scale cold storage facility for silkworm eggs in Japan, making use of natural cold air flow.

Download

■Tomioka Silk Mill and Related Sites

Booklet(English) : (6.9MB)

Booklet(English) : (6.9MB)